|

|

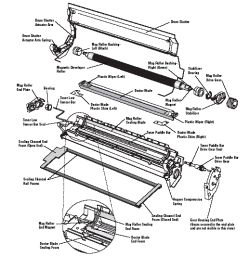

| Waste

Bin Section |

Roller

Housing |

(

Please click on a image to view larger version )

TECHNICAL

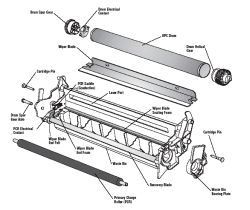

Mentioned below in brief is the printing process:

In one of

the stages the primary charge roller places a

uniform negative DC bias voltage on the opc drum surface. The

amount of the negative DC bias placed on the drum is controlled

by the printers intensity setting. This process is called conditioning.

Hence the need to change the primary charge roller every cycle

to give a uniform negative DC bias. Non compliance of the above

might lead to faulty printing

In another

stage the laser beam is fired on to a rotating mirror called the

scanner. As the mirror rotates, the beam reflects into a set of burberry bags outlet

focusing lens. The beam then strikes the opc surface leaving a

latent electrostatic image on the drum. The opc drum

should be mint new, as otherwise image distortion would take place

In secondary

stages the toner image is developed on the drum by the developing

section which contains the toner particle. The toner is held to

the magnetic roller sleeve by the stationery magnet inside the

sleeve and the DC bias voltage supplied by the high voltage power

supply. Critical to note here is that the toner powder

used, should be of the highest quality for proper attraction by

the magnetic sleeve. Also important to note is that the magnetic

sleeve is to be replaced in all cycles due to its critical

function of proper attraction of the toner powder.

In the waste

bin section, the wiper blade performs the all

important function of cleaning the opc drum. If the blade is not

changed, it leads to flip overs and spills leading to dots over

the printout and subsequent printer damage. Hence it is imperative

to change the wiper blade very cycle.

CONCLUSION:

The five critical

components mentioned above are a must for proper functioning of

the cartridge and need to be replaced every cycle.

info@visheshcartridge.com

info@visheshcartridge.com